Factory making High Strength Polyethylene Foam Board - LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners – Bluestone

Factory making High Strength Polyethylene Foam Board - LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners – Bluestone Detail:

Why use polypropylene(PP) foam board as material box?

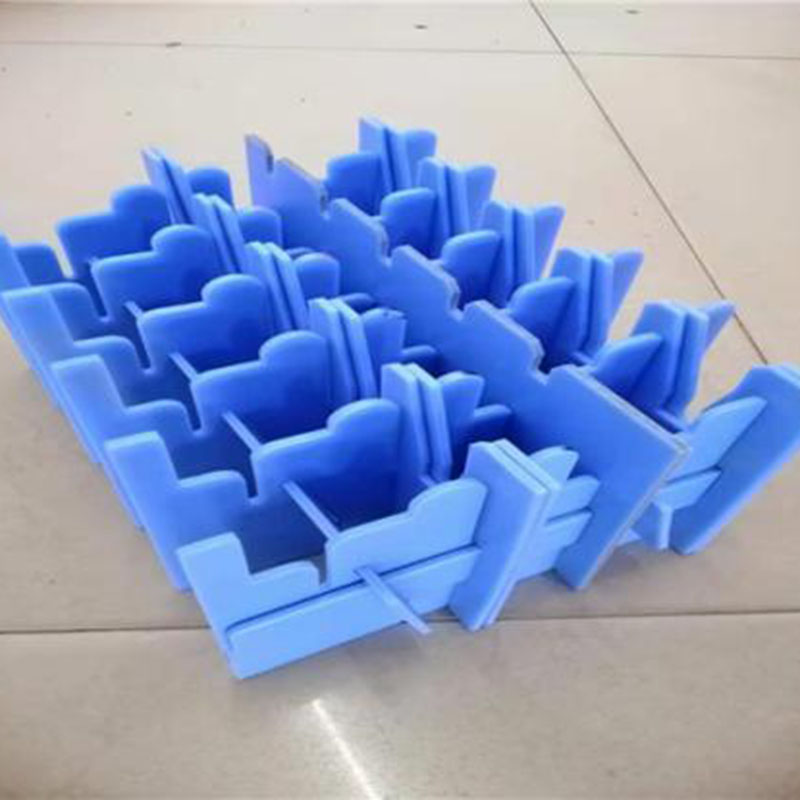

The material box is suitable for various industries and occasions with a wide range of applications.It can be used to store food, with convenient cleaning, convenient parts turnover, neat stacking and easy management.Reasonable design, excellent quality. It is applicable to transportation, distribution, storage, circulation and processing in factory logistics.If you choose polypropylene(PP) foam board as material box.Light weight to meet the requirements of box weight.Good strength to deal with the damage when falling.According to the maximum load requirement of the box, choose different thickness of the board.Polypropylene material is resistant to high temperature and corrosion.Heat insulation, sound insulation,machinability,low temperature resistance, resilience, etc. are very good.It can be made into not only a material box, but also a material box with a cover.

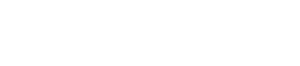

Why use the fasteners to assembled the material box?

The material box can be made by various processing methods.For example, electrode welding, Hot melt welding,fix with nails, etc.The technical requirements of electrode welding are relatively high.But the polypropylene(PP) foam sheet material box assembled by our fasteners is relatively simple to operate.Only need to order the foam sheets and fasteners, which can be assembled by yourselves.It can also save labor cost and shipping rates.As assembled boxes are easily damaged during transportation, we usually sell only polypropylene(PP) foam boards not finished products.

If you are interested in our boards, please contact us.

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Factory making High Strength Polyethylene Foam Board - LOWCELL polypropylene(PP) foam sheet material box assembled by fasteners – Bluestone , The product will supply to all over the world, such as: Luxembourg, Argentina, Salt Lake City, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!