Factory making High Strength Polyethylene Foam Board - LOWCELL Protective backing board of liquid crystal glass – Bluestone

Factory making High Strength Polyethylene Foam Board - LOWCELL Protective backing board of liquid crystal glass – Bluestone Detail:

What is the advantage of foamed polypropylene (PP) board as protective board?

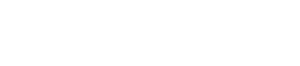

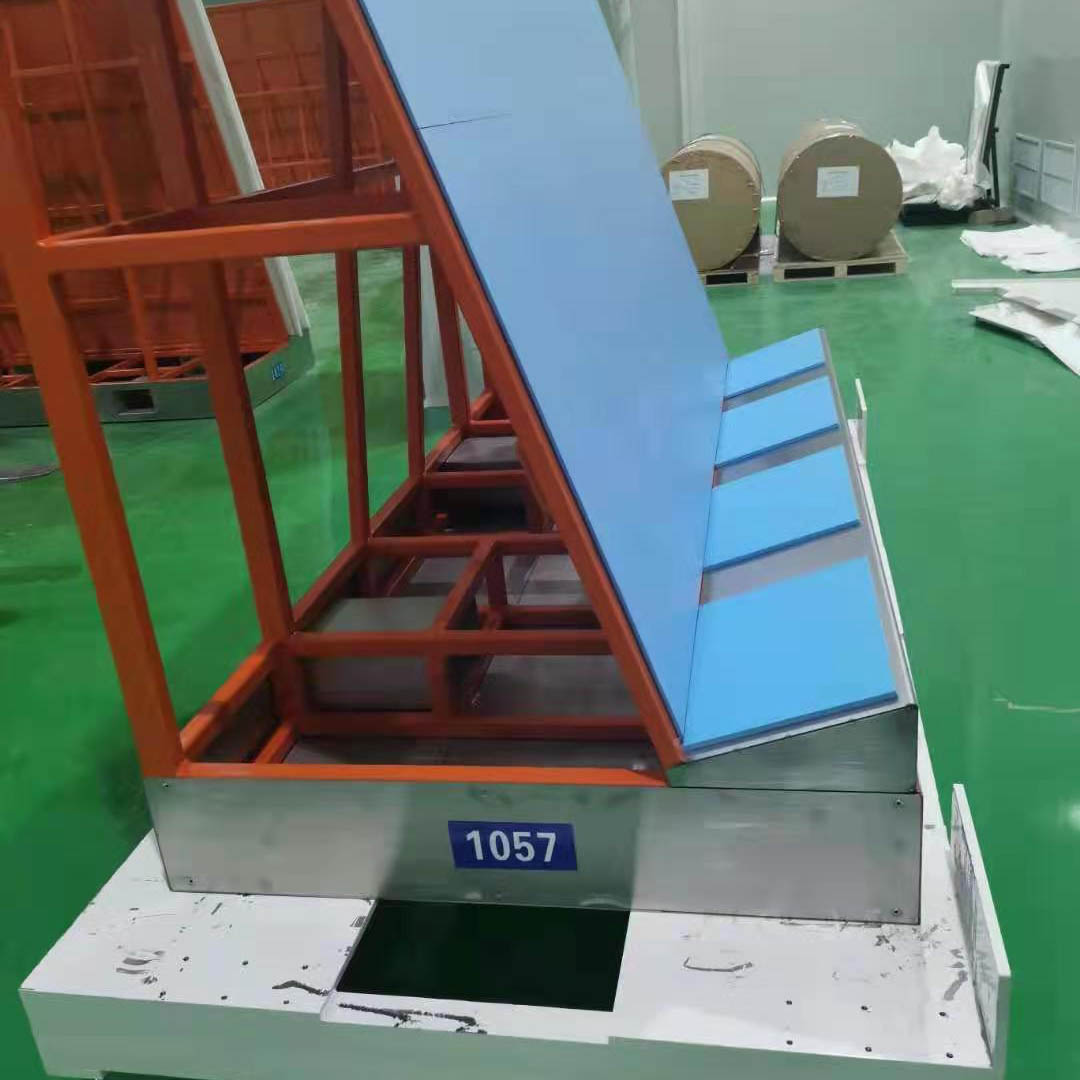

Polypropylene (PP) foam board is not only environmentally friendly and recyclable, but also can ensure good cushioning while reducing the overall packaging weight, so as to play an adequate safety protection role for fragile glass materials. Its moderate foaming ratio brings various superior physical properties, which can not only ensure its sufficient strength and load-bearing requirements, but also have excellent cushioning and shockproof performance. It does not fade or chip off. Because of its excellent waterproof, mildew proof, corrosion resistance, it is easy to clean. Its service life can reach at least 3-4 years, and it is also very convenient to replace. This kind of material is the best packaging material commonly recognized by well-known LCD glass enterprises all over the world. Lowcell has been able to replace the world’s leading Japanese similar materials. At present, it is widely used by industry-leading enterprises such as Corning in the United States, Asahi Glass in Japan, Samsung in Korea and CAIHONG in China. Conventional colors are blue and green, and other colors can be customized. The maximum width is 1300mm and the length is 2000-3000mm, which can meet the packaging size requirements of various generations of glass products. Conventional packaging is to pack several sheets with plastic film before palletizing.

Product detail pictures:

Related Product Guide:

Our commission would be to serve our customers and clientele with very best excellent and aggressive portable digital products for Factory making High Strength Polyethylene Foam Board - LOWCELL Protective backing board of liquid crystal glass – Bluestone , The product will supply to all over the world, such as: Cambodia, Malaysia, USA, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

A good manufacturers, we have cooperated twice, good quality and good service attitude.