-

Quots for Foot Stretch Brace Plate Adjustable Slant Board for Calf Stretching

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

Factory made hot-sale Resistance Light Weight PP Foam Rigid Screen Printing Plastic PP Grey White Clear Transparent Color Rigid Sheet Board for Printing Packing Thermoforming

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

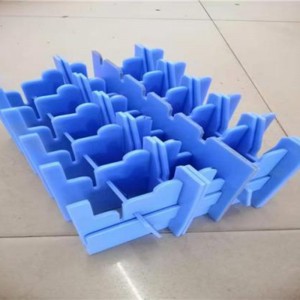

PP Foam Board Further Processing Corrugated Board

LOWCELL polypropylene(PP) foam sheet is Carbon dioxide(CO2) SCF non-crosslinked with closed cell foam extrusion.This is better multi-purpose materials. The foam sheet is lighter, higher strength, fully recyclable,smooth surface and low VOC. Mostly use polypropylene(PP)foam sheet(expanded 3 times) as packaging inner material.The product lineup offers greater benefits by using the general-, antistatic- and conductive-grade products according to the usage environment.According to your needs, we can customize any shape of partition materials.Colors can also be customized.

-

Well-designed Tecon High Density White and Color Good Price PP Panelconstruction Material Plastic Sheet PP Foam Board

LOWCELL polypropylene(PP) foam sheet is Carbon dioxide(CO2) SCF non-crosslinked with closed cell foam extrusion.This is better multi-purpose materials. The foam sheet is lighter, higher strength, fully recyclable,smooth surface and low VOC. Mostly use polypropylene(PP)foam sheet(expanded 3 times) as packaging inner material.The product lineup offers greater benefits by using the general-, antistatic- and conductive-grade products according to the usage environment.According to your needs, we can customize any shape of partition materials.Colors can also be customized.

-

Quots for Expanded White PP Foam Board for Signs

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.4-0.45g/cm3, and the thickness specifications are available in different thicknesses of 3-5mm. Compared with traditional solid polyethylene materials, it has many obvious advantages. First of all, the cost of the board is close to that of traditional polyethylene solid boards, and there will be no pressure to increase costs. Secondly, the high-temperature resistance of the raw material polypropylene itself can ensure that it is not easily deformed in high-temperature environments; good low-temperature resistance can also improve its strength and prevent it from becoming brittle in low-temperature environments.

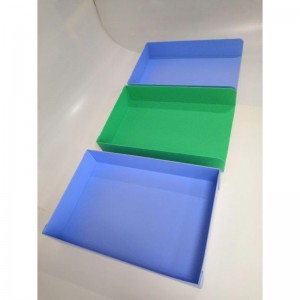

We launch this transfer box made of high-quality 3 times PP foam board. It is a multi-functional transfer product suitable for pharmaceutical, food and cosmetics industries. It has excellent thermal insulation properties and compressive strength to protect products from damage during transit. Primarily designed to meet the needs of the pharmaceutical, food and cosmetics industries, it ensures the safe transit and storage of products. It has a lightweight design that is easy to carry and stack, which can save transportation and storage space. Moreover, the box adopts a drawer-type design for easy access and storage of products. This design not only reduces friction during storage of products, but also provides convenience of use.

-

High Quality for Digital Printed PP Foam Board Sign / PP Sheet Advertising Sign Paper Board

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

PP Free Foam Board for Sign

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

Decoration Custom PP Sign Foam Board Photobooth Props

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

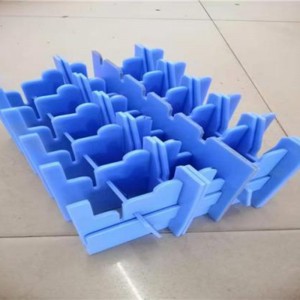

Best Price for 10mm 12mm 15mm 18mm 20mm Sandwich Foam Core 4X8 Colored Grey PP Board

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.4-0.45g/cm3, and the thickness specifications are available in different thicknesses of 3-5mm. Compared with traditional solid polyethylene materials, it has many obvious advantages. First of all, the cost of the board is close to that of traditional polyethylene solid boards, and there will be no pressure to increase costs. Secondly, the high-temperature resistance of the raw material polypropylene itself can ensure that it is not easily deformed in high-temperature environments; good low-temperature resistance can also improve its strength and prevent it from becoming brittle in low-temperature environments.

We launch this transfer box made of high-quality 3 times PP foam board. It is a multi-functional transfer product suitable for pharmaceutical, food and cosmetics industries. It has excellent thermal insulation properties and compressive strength to protect products from damage during transit. Primarily designed to meet the needs of the pharmaceutical, food and cosmetics industries, it ensures the safe transit and storage of products. It has a lightweight design that is easy to carry and stack, which can save transportation and storage space. Moreover, the box adopts a drawer-type design for easy access and storage of products. This design not only reduces friction during storage of products, but also provides convenience of use.

-

Best Price for Best Quality One Way Transparent Rigid PP Hanging Sign Board

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

High Performance Resistance Light Weight PP Foam Rigid Screen Printing Plastic PP Grey White Clear Transparent Color Rigid Sheet Board for Printing Packing Thermoforming

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence

-

OEM Manufacturer High Strength 3mm PP Free Foam Board for Advertising Sign

Lowcell is a supercritical non-crosslinked continuously extruded foamed polypropylene board with a closed-cell independent cell structure. The foaming ratio is 3 times, the density is 0.35-0.45g/cm3, and different thicknesses of 2-5mm are available according to the use occasion. Because of its excellent waterproof, mildew-proof, corrosion resistance and easy cleaning, its service life can reach at least 3 years. This PP foam plate filter splint disc is designed to meet the requirements of environments with high filtration requirements. It is made of PP foam board material, which can ensure that the product will not shed debris during use, thereby avoiding contamination of the product. This lightweight material makes the plywood more convenient to carry and install, improving the convenience of use of the product. In addition to being lightweight, non-shedding, and impact-resistant, this plywood disc is also non-toxic and harmless. After multiple tests, it has been confirmed that it will not cause any harm to the environment and the human body. It is a very Safe material. When you use this product, you don’t have to worry about negative impacts on the environment and the product itself, and you can use it with confidence