Lowest Price for China PP Film Production Line Polypropylene Sheets Extrusion Line

We constantly stick to the theory “Quality To start with, Prestige Supreme”. We have been fully committed to offering our consumers with competitively priced quality products and solutions, prompt delivery and qualified service for Lowest Price for China PP Film Production Line Polypropylene Sheets Extrusion Line, We invites both you and your enterprise to thrive along with us and share a vibrant long term in global sector.

We constantly stick to the theory “Quality To start with, Prestige Supreme”. We have been fully committed to offering our consumers with competitively priced quality products and solutions, prompt delivery and qualified service for China Polypropylene Sheets Extrusion Line, Sheet Extrusion Machine, now we have complete material production line, assembling line , quality control system, and the most importantly, we have now many patents technology and experienced technical&production team, expert sales service team. With all those people advantages, we’re about to create”the reputable international brand of nylon monofilaments”, and spreading our products and solutions to every corner of the world. We’re keep moving and try our best to serve our customers.

What are the advantages?

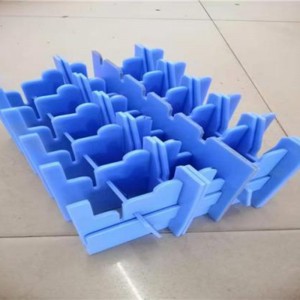

Firstly, the cost of the PP foam board is close to that of traditional polyethylene solid board, and there will be no pressure of cost increase. However, the quality of thermoforming will be greatly improved, which can almost reach the level of ABS board. Because of its excellent melt viscosity after foaming, it is not easy to break bubbles when blistering and blowing, the thickness of the board is uniform, it is easier to form, and the processing defect rate is greatly reduced. Of course, the processing conditions of the material, such as heating temperature and time, will be slightly different from those of traditional solid polyethylene board, and need to be reset. In addition, due to the foaming principle of the foaming material, when the material surface is scratched with sharp objects, the bubble structure on the surface has excellent elasticity, which will only produce depression and will not drop debris like the traditional solid plastic board. Products with high requirements for packaging cleanliness are most suitable, such as metal castings such as automobile engine and gearbox. The conventional color is black. You can also customize various colors and metallic or fluorescent colors. The maximum width can reach 1300mm, and the length is unlimited from 2000 to 3000mm. Conventional packaging is to pack several sheets with plastic film before palletizing.

We constantly stick to the theory “Quality To start with, Prestige Supreme”. We have been fully committed to offering our consumers with competitively priced quality products and solutions, prompt delivery and qualified service for Lowest Price for China PP Film Production Line Polypropylene Sheets Extrusion Line, We invites both you and your enterprise to thrive along with us and share a vibrant long term in global sector.

Lowest Price for China Polypropylene Sheets Extrusion Line, Sheet Extrusion Machine, now we have complete material production line, assembling line , quality control system, and the most importantly, we have now many patents technology and experienced technical&production team, expert sales service team. With all those people advantages, we’re about to create”the reputable international brand of nylon monofilaments”, and spreading our products and solutions to every corner of the world. We’re keep moving and try our best to serve our customers.