Short Lead Time for 1.3 Times Polypropylene Foam Board - LOWCELL polypropylene(PP) foam sheet partition materials – Bluestone

Short Lead Time for 1.3 Times Polypropylene Foam Board - LOWCELL polypropylene(PP) foam sheet partition materials – Bluestone Detail:

Product Description

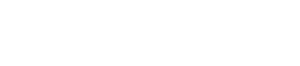

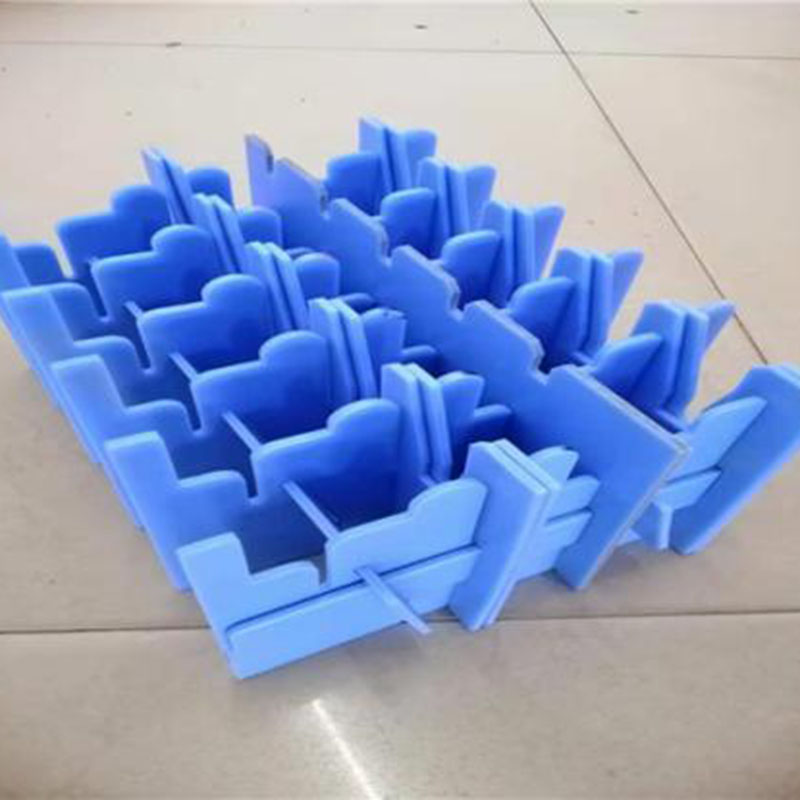

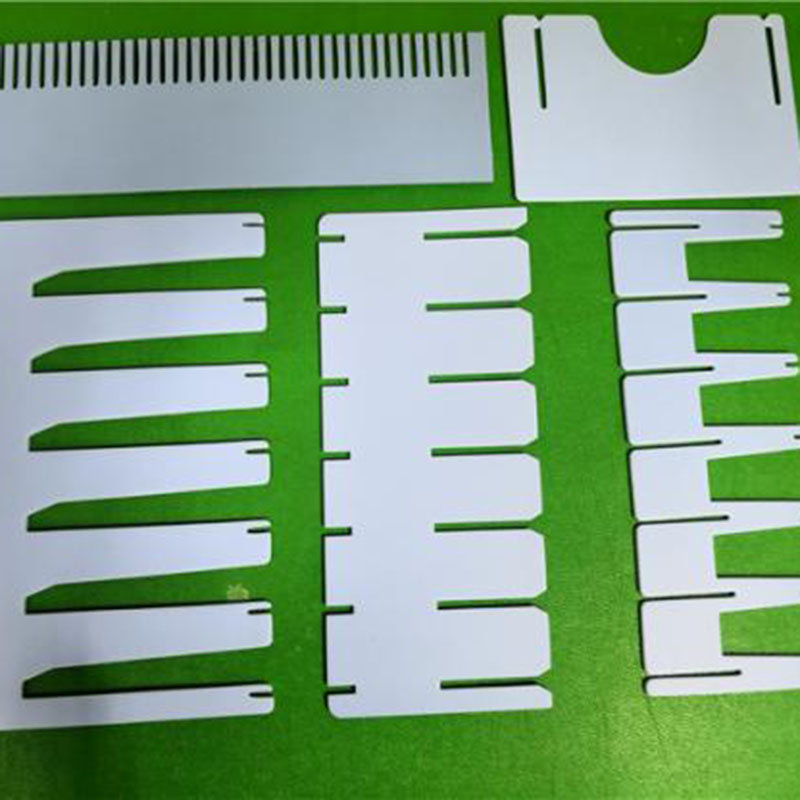

LOWCELL polypropylene(PP) foam sheet is an environment-friendly material in a sanitary, harmless for the carbon dioxide foam.It has excellent workability.It is widely used in packaging, machinery, light industry, postal service, food packaging, etc.Our polypropylene(PP) foam sheet is also qualified in the inspection of food grade polypropylene packaging.According to your needs, you can choose boards of different thickness to make partitions.

LOWCELL polypropylene(PP) foam sheet is an ideal material to replace ordinary polypropylene hollow board.The weight is higher than that of hollow boards because they are hollow and our boards are solid.The properties are better than hollow boards in many aspects.Although the cost is higher than that of hollow plate, the service time is more than 2-3 times that of hollow plate.The partitions can be used with the turnover box.It can also be used in the coaming box、pipeline truck、material box、etc.So that the parts can be placed neatly and easy to take from the turnover box. It can also avoid scratching parts.Foamed polypropylene(PP)lining of surface compound protective foam will be better buffering.According to the requirements, the sheet can be molded into various shapes.

Standard products

LOWCELL polypropylene(PP) foam sheet is an environment-friendly material in a sanitary, harmless for the carbon dioxide foam.It has excellent workability.It is widely used in packaging, machinery, light industry, postal service, food packaging, etc.Our polypropylene(PP) foam sheet is also qualified in the inspection of food grade polypropylene packaging.According to your needs, you can choose boards of different thickness to make partitions.

LOWCELL polypropylene(PP) foam sheet is an ideal material to replace ordinary polypropylene hollow board.The weight is higher than that of hollow boards because they are hollow and our boards are solid.The properties are better than hollow boards in many aspects.Although the cost is higher than that of hollow plate, the service time is more than 2-3 times that of hollow plate.The partitions can be used with the turnover box.It can also be used in the coaming box、pipeline truck、material box、etc.So that the parts can be placed neatly and easy to take from the turnover box. It can also avoid scratching parts.Foamed polypropylene(PP)lining of surface compound protective foam will be better buffering.According to the requirements, the sheet can be molded into various shapes.

|

NO. |

Thickness(mm) |

Width(mm) |

Length(mm) |

color |

|

1 |

1.2 |

1000 |

2300 |

Blue |

|

2 |

2.0 |

1000 |

2000 |

Blue |

|

3 |

2.5 |

1000 |

2000 |

Blue |

|

4 |

3.0 |

1000 |

2000 |

Blue |

|

5 |

4.0 |

1000 |

2000 |

Blue |

|

6 |

5.0 |

1000 |

2000 |

Blue |

|

7 |

7.0 |

1000 |

2000 |

Blue |

|

8 |

9.0 |

930 |

2780 |

Blue |

|

9 |

10.0 |

1120 |

2440 |

Blue |

Please contact us if you have other size requirements.

Thickness range: 1-10mm.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Short Lead Time for 1.3 Times Polypropylene Foam Board - LOWCELL polypropylene(PP) foam sheet partition materials – Bluestone , The product will supply to all over the world, such as: Washington, Johor, Hyderabad, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.